Hi everyone,

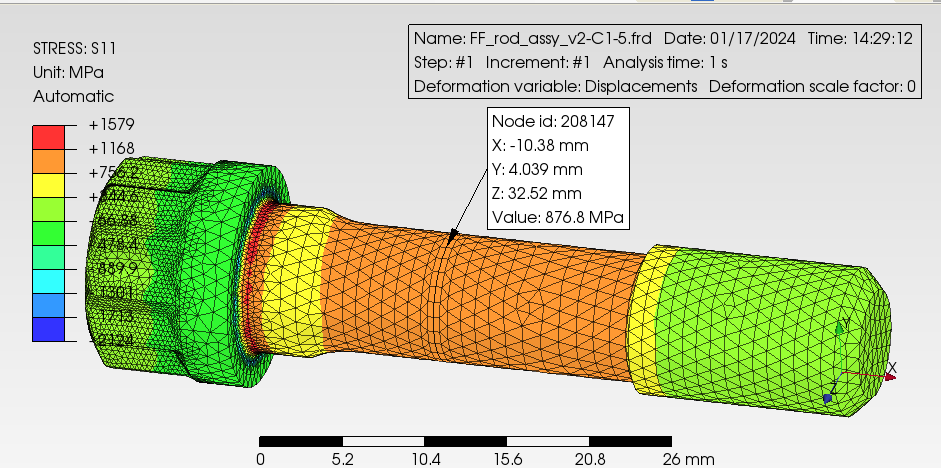

I’m trying to understand the Preload load type better. I have a simple example of with two bolts. The thread is connected to the part with a tie and the other interfaces are all surface-surface contacts (Type Hard, friction coefficient 0.1). I followed the YouTube tutorial by Matej Borovinšek and finally got both preloads to work, BUT the stress in the bolt shank appears to be very low. The preload is 45 kN and the shank cross section is 51.672 mm^2, giving a nominal stress of 870 MPa. The S11 stress at the surface of the shank is between 32 and 38 MPa. Also the stress pattern in the shank is like the one shown in the Pre-tension - Bolt tutorial before the boundary layer is created at the interface. The contact force at the underhead interface is only 2135 N, which corresponds to a nominal stress in the shank of 41.3 MPa, similar to the reported value.

What am I doing wrong? Does the thickness of the boundary layer need increasing?

I have uploaded a plot of the bolt stress.

Regards,

Rod