Hello,

I am new to PrePoMax and would really appreciate your help. I am trying to simulate an aircraft structure made of carbon fiber material with 2 mm thickness, and I have several questions:

1) Linear vs Nonlinear Simulation?

My aircraft model is hollow and approximately weighs 1700 kg. I want to know:

Should I perform the simulation using linear or nonlinear analysis to get more realistic and accurate results for such a lightweight yet large structure?

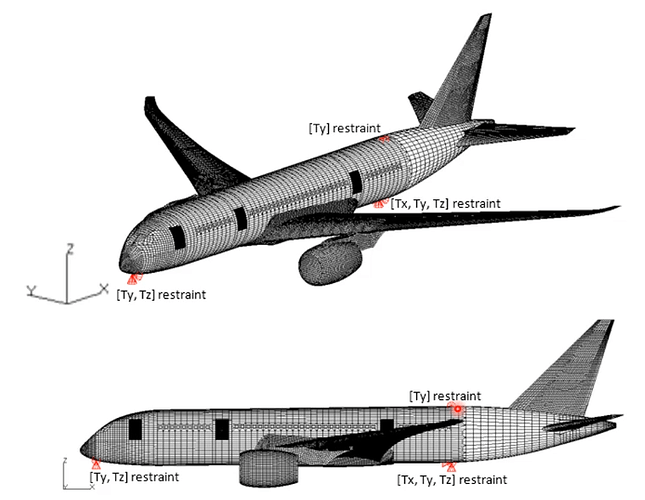

2) Load & Boundary Conditions Help

I’m facing trouble with the load setup and boundary conditions:

- I applied Lift force upwards

- I applied Gravity downwards

- I fixed the bottom of the fuselage

But I am confused about how to correctly apply Thrust and Drag forces.

What would be the correct way to represent them and where should I apply those boundary conditions?

3) How to Validate Simulation?

Once I run the simulation,

How can I validate the results?

Should I compare it with a handbook, physical tests, or another method?

Please guide me through this. I am doing this as part of my professional journey. Sometimes, a small tip from an experienced professional can save days of trial and error for someone just starting out. If you have any insights, resources, or suggestions, i’d truly appreciate your support - even a brief conversation would be incredibly helpful.

Thank you in advance for your time and Guidance!