maybe it can start by single element to understand clearly regarding surface spring and traction implemented in PrePoMax.

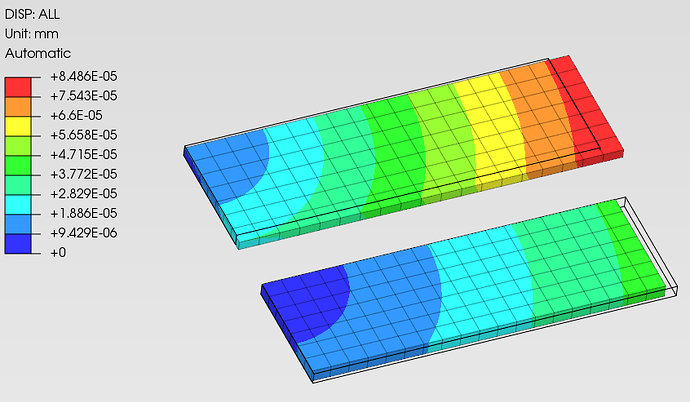

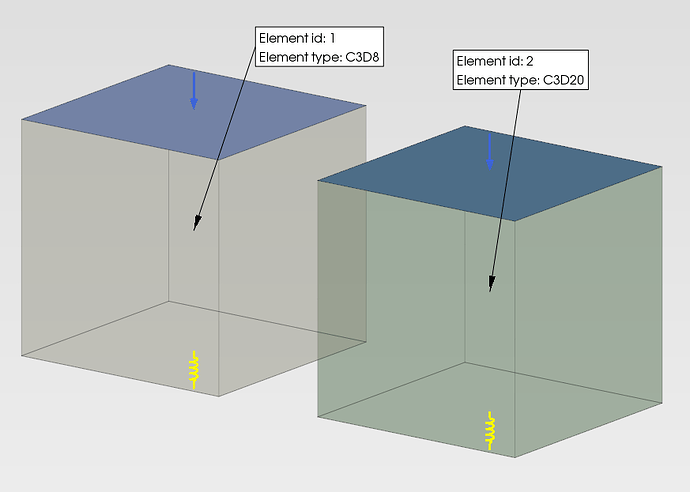

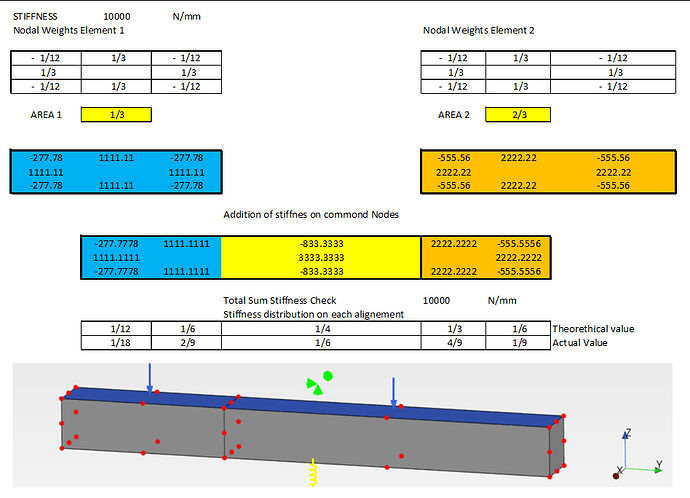

validation and verification of linear spring can take from external reference such as textbook or paper, this can be review for both linear and quadratic element also.

in case compression-only by gap element, it’s actually simplification problem of elastic contact. Comparable with full model (two part) with penalty contact or tied contact with stiffness overrides.

**

** Heading +++++++++++++++++++++++++++++++++++++++++++++++++

**

*Heading

Hash: uyOtHNO2, Date: 11/27/2023, Unit system: MM_TON_S_C

**

** Nodes +++++++++++++++++++++++++++++++++++++++++++++++++++

**

*Node

1, 0.00000000E+000, 1.00000000E+000, 0.00000000E+000

2, 0.00000000E+000, 0.00000000E+000, 0.00000000E+000

3, 1.00000000E+000, 1.00000000E+000, 0.00000000E+000

4, 1.00000000E+000, 0.00000000E+000, 0.00000000E+000

5, 0.00000000E+000, 1.00000000E+000, 5.00000000E-001

6, 0.00000000E+000, 0.00000000E+000, 5.00000000E-001

7, 1.00000000E+000, 0.00000000E+000, 5.00000000E-001

8, 1.00000000E+000, 1.00000000E+000, 5.00000000E-001

9, 0.00000000E+000, 5.00000000E-001, 0.00000000E+000

10, 5.00000000E-001, 1.00000000E+000, 0.00000000E+000

11, 1.00000000E+000, 5.00000000E-001, 0.00000000E+000

12, 5.00000000E-001, 0.00000000E+000, 0.00000000E+000

13, 0.00000000E+000, 5.00000000E-001, 5.00000000E-001

14, 5.00000000E-001, 0.00000000E+000, 5.00000000E-001

15, 1.00000000E+000, 5.00000000E-001, 5.00000000E-001

16, 5.00000000E-001, 1.00000000E+000, 5.00000000E-001

17, 1.00000000E+000, 0.00000000E+000, 2.50000000E-001

18, 0.00000000E+000, 0.00000000E+000, 2.50000000E-001

19, 1.00000000E+000, 1.00000000E+000, 2.50000000E-001

20, 0.00000000E+000, 1.00000000E+000, 2.50000000E-001

**

** Elements ++++++++++++++++++++++++++++++++++++++++++++++++

**

*Element, Type=C3D20, Elset=Solid_part-1

1, 1, 2, 4, 3, 5, 6, 7, 8, 9, 12, 11, 10, 13, 14, 15,

16, 20, 18, 17, 19

*Element, Type=SPRING1, Elset=Surface_Spring-1_All

2, 1

3, 2

4, 4

5, 3

6, 9

7, 12

8, 11

9, 10

**

** Node sets +++++++++++++++++++++++++++++++++++++++++++++++

**

*Nset, Nset=Internal-1_Internal_Selection-1_Surface_Spring-1_Master

1, 2, 3, 4, 9, 10, 11, 12

*Nset, Nset=Internal-1_Internal_Selection-1_Surface_Traction-1

5, 6, 7, 8, 13, 14, 15, 16

*Nset, Nset=Internal_Selection-1_Displacement_Rotation-1

5

**

** Element sets ++++++++++++++++++++++++++++++++++++++++++++

**

*Elset, Elset=Internal-1_Internal_Selection-1_Surface_Spring-1_Master_S1

1

*Elset, Elset=Internal-1_Internal_Selection-1_Surface_Traction-1_S2

1

*Elset, Elset=Surface_Spring-1_1_DOF_3

2

*Elset, Elset=Surface_Spring-1_2_DOF_3

3

*Elset, Elset=Surface_Spring-1_4_DOF_3

4

*Elset, Elset=Surface_Spring-1_3_DOF_3

5

*Elset, Elset=Surface_Spring-1_9_DOF_3

6

*Elset, Elset=Surface_Spring-1_12_DOF_3

7

*Elset, Elset=Surface_Spring-1_11_DOF_3

8

*Elset, Elset=Surface_Spring-1_10_DOF_3

9

**

** Surfaces ++++++++++++++++++++++++++++++++++++++++++++++++

**

*Surface, Name=Internal_Selection-1_Surface_Spring-1_Master, Type=Element

Internal-1_Internal_Selection-1_Surface_Spring-1_Master_S1, S1

*Surface, Name=Internal_Selection-1_Surface_Traction-1, Type=Element

Internal-1_Internal_Selection-1_Surface_Traction-1_S2, S2

**

** Physical constants ++++++++++++++++++++++++++++++++++++++

**

**

** Materials +++++++++++++++++++++++++++++++++++++++++++++++

**

*Material, Name=S235

*Density

7.8E-09

*Elastic

210000, 0.28

*Expansion, Zero=20

1.1E-05

*Conductivity

14

*Specific heat

440000000

**

** Sections ++++++++++++++++++++++++++++++++++++++++++++++++

**

*Solid section, Elset=Solid_part-1, Material=S235

*Spring, Elset=Surface_Spring-1_1_DOF_3

3

-8.33333333E+001

*Spring, Elset=Surface_Spring-1_2_DOF_3

3

-8.33333333E+001

*Spring, Elset=Surface_Spring-1_4_DOF_3

3

-8.33333333E+001

*Spring, Elset=Surface_Spring-1_3_DOF_3

3

-8.33333333E+001

*Spring, Elset=Surface_Spring-1_9_DOF_3

3

333.333333333333

*Spring, Elset=Surface_Spring-1_12_DOF_3

3

333.333333333333

*Spring, Elset=Surface_Spring-1_11_DOF_3

3

333.333333333333

*Spring, Elset=Surface_Spring-1_10_DOF_3

3

333.333333333333

**

** Pre-tension sections ++++++++++++++++++++++++++++++++++++

**

**

** Constraints +++++++++++++++++++++++++++++++++++++++++++++

**

**

** Surface interactions ++++++++++++++++++++++++++++++++++++

**

**

** Contact pairs +++++++++++++++++++++++++++++++++++++++++++

**

**

** Amplitudes ++++++++++++++++++++++++++++++++++++++++++++++

**

**

** Initial conditions ++++++++++++++++++++++++++++++++++++++

**

**

** Steps +++++++++++++++++++++++++++++++++++++++++++++++++++

**

**

** Step-1 ++++++++++++++++++++++++++++++++++++++++++++++++++

**

*Step

*Static

**

** Output frequency ++++++++++++++++++++++++++++++++++++++++

**

*Output, Frequency=1

**

** Boundary conditions +++++++++++++++++++++++++++++++++++++

**

*Boundary, op=New

** Name: Displacement_Rotation-1

*Boundary

Internal_Selection-1_Displacement_Rotation-1, 1, 1, 0

Internal_Selection-1_Displacement_Rotation-1, 2, 2, 0

**

** Loads +++++++++++++++++++++++++++++++++++++++++++++++++++

**

*Cload, op=New

*Dload, op=New

** Name: Surface_Traction-1

*Cload

5, 3, 83.3333333333333

8, 3, 83.3333333333333

7, 3, 83.3333333333333

6, 3, 83.3333333333333

16, 3, -3.33333333E+002

15, 3, -3.33333333E+002

14, 3, -3.33333333E+002

13, 3, -3.33333333E+002

**

** Defined fields ++++++++++++++++++++++++++++++++++++++++++

**

**

** History outputs +++++++++++++++++++++++++++++++++++++++++

**

**

** Field outputs +++++++++++++++++++++++++++++++++++++++++++

**

*Node file

RF, U

*El file

S, E, NOE

**

** End step ++++++++++++++++++++++++++++++++++++++++++++++++

**

*End step