¿Are the nodes projected into the geometry?

Contact won’t work between the surfaces defined like this:

Both tie constraints and contact search for master surfaces in the direction normal to the slave surface. With tie constraints, you can specify tolerance to increase the default search distance and it may work (without adjustment because it would distort the mesh) even on large distances.

Regarding the wound version, did you try with Thicken Shell Mesh and then defining contact/constraints on solids ?

I see, I guess if contacts could be found, the closest slave nodes be connected with the closest master nodes, right?

I have not explored the thicken shell mesh option further, since I wasn’t able to pick different thicknesses for the layers like I could with the composite.

From your answer I gather that I practically have to go with some version of the wound model, as thermally coupling the layers the way I need to couple them will be difficult/impossible in the unwound model, right?

Could you post your file as *inp?

Tie constraints would be more appropriate since you can change the position tolerance even to a large distance but the surfaces have to face each other. Contact is good when components are touching (or almost touching and you can use adjustment to move the slave nodes so that they lie exactly on the master surface). It’s also more computationally expensive.

There are some ways to thermally link regions in various simulation software. In CalculiX, you would have to use something like equation constraints (*EQUATION - not implemented in PrePoMax yet, requires keyword edits) to define that (thermal) DOF on one side should be equal to (thermal) DOF on the other side. But defining this is not so straightforward.

Are you aware that with actuall layer thicknesses there is a gap between them.?

Additionally, your node distribution is not uniform.

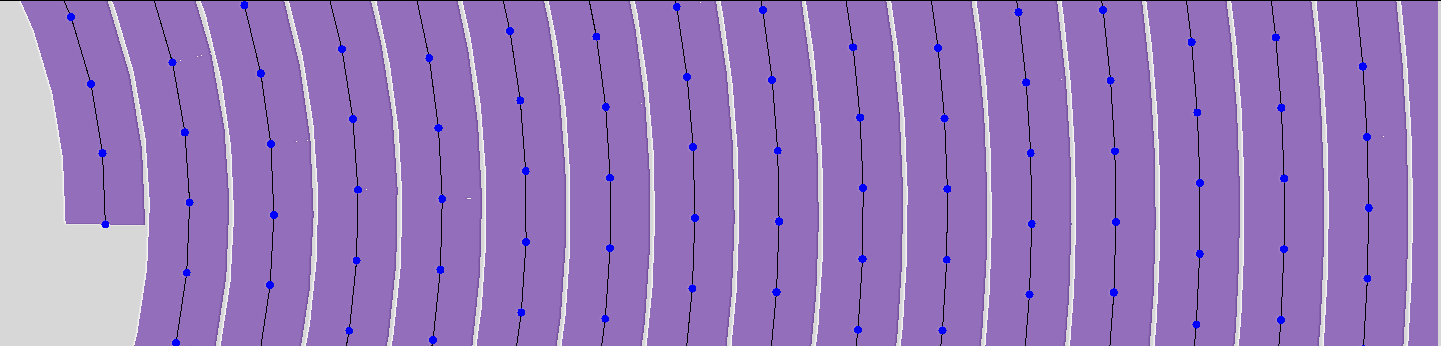

Desirable node distribution. Second order elements and Projected into the geometry.

I will try to get some working model. I will compact them slightly to remove that gap.

I would say it’s all about building a good mesh.

The one attached has contact defined and it woks. Mesh has been manually build.

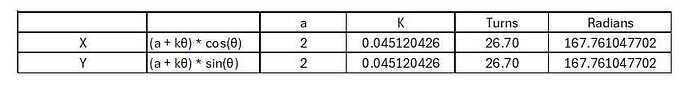

It is made from a spiral and conecting the points (into beams). Bems are later extruded to generate the shells.This are the spiral parameters.

Battery Prepomax.inp (378.3 KB)

Thank you for your efforts, I imported the model and had the following error:

Is it possible to run an analysis in PrePoMax with the model?

You can’t import features unsupported in PrePoMax (such as composite sections) from input files. In fact, the .inp file importer is quite outdated compared to the exporter. Thus, in such cases when working with input files, you should run analyses with standalone CalculiX (instructions here: Using standalone CalculiX) and only postprocess them in PrePoMax (import .frd file with results).