Hi all, I am going crazy with what looks like a very simple problem.

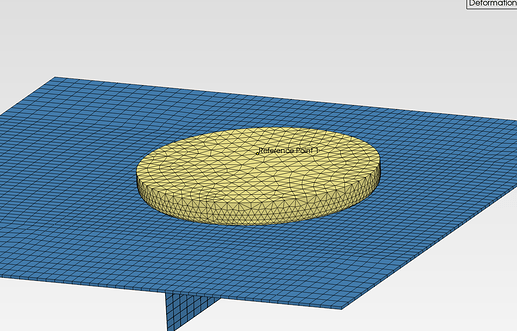

It is a deck structure (the only challenge should be dealing with the thousands of parts)

but when I tried establish contact between a solid part (normal or rigid) and a shell model where there is a beam or stringer directly under the object I cannot get proper convergence, even with a very simple test model.

I would like to have quad mesh on the solid part but I haven’t done that as I need to use Netgen or something externally. Anyway I don’t think that is the real issue here.

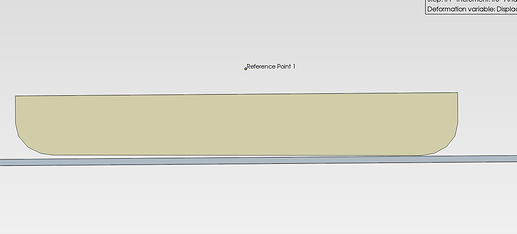

I am doing everything I can think of to make my test easy to converge. The edge has a fillet, the part is slightly tilted so the contact will be gradual, the solid is constrained and there is only a small displacement with tiny initial steps. I have been working with exponential contact to see if that will work and while it will run it never manages to actually establish contact. (This is a version of the pmx file). I also tired converting the solid to be rigid and that didn’t seem to make any difference.

If anyone has any ideas I would be very appreciative. I am completely confused why this isn’t straight forward but the extra stiffness from the stringer must somehow really mess up the contact.

Thanks

Luke